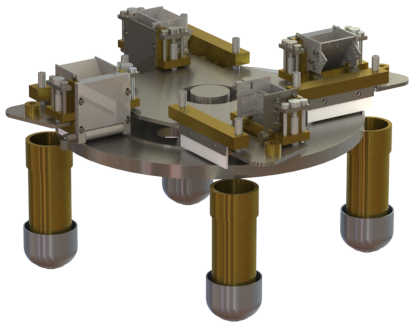

The SpreadStation Powder Analyzer measures the spreadability of powders by actually spreading powders in a layer and then analyzing the properties of the layer.

|

Powder is loaded into a spreading device that includes a feeder and a spreading plate. The spreading device rests on a build plate and has an adjustable gap at the bottom to control the powder layer thickness. The build plate is rotated to create linear motion between the spreading device and the build plate. This linear motion spreads the powder in a layer on the build plate. Images of the created layer are captured and the thickness of the layer is measured using a laser distance sensor. The layer is then removed from the build plate by a scraping blade and is weighed.

|

| The SpreadStation can be equipped with up to four spreaders and the build plate can be a solid plate or a powder bed. Spreading speed is programmable from 1 to 300 mm/s. Spreading layer thickness can be set from 20 micrometers to 2 millimeters. The build area can be heated to 250C. |  |

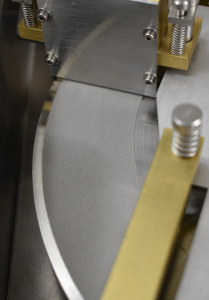

Images of good spreading and poor spreading alloy

|

good spreading |

poor spreading |